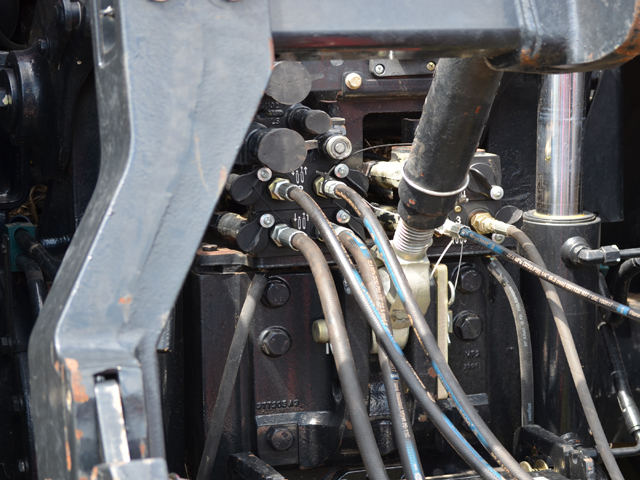

Hydraulic systems are used in a variety of applications, such as large and small manufacturing environments, as well as constructions, industrial machinery, and cars. Hydraulic equipment is frequently employed in industries such as processing plants, forest management, metalworking, robotics hydraulikaggregat, and steel processing. As a productive and cost-effective method of generating movement or repeatability, hydraulic system-based technology is tough to surpass. Because of these considerations, it is likely that your company use hydraulic system in one or more situations.

A hydraulic cylinder is a system that turns the energy contained in drilling pump into a force that may be utilised to drive the cylinder in a straight line. It, too, has a wide range of uses and can be used for single or double functioning. The chambers, as part of the overall hydraulic system, initiate the hydrostatic pressure, the movement of which is controlled by a hydraulic circuit.

An Introduction to Hydraulic Systems

The function of a particular hydraulic system may differ, yet all hydraulic systems operate on the same basic premise. Simply said Hydraulic aggregate, hydraulic systems work and accomplish tasks by utilising a pressurised fluid. Another way to say it is that the pressurised fluid makes everything operate. Because of the tremendous power of liquid fuel in hydraulics, hydraulics are often utilised in heavy machinery. Pressure applied to a confined fluid at any point in a hydraulic system is transferred unchanged. That pressurised fluid exerts force or power on every component of the segment of a contained vessel. Operators can lift big loads and do other tasks as a result of the utilisation of this force, which varies depending on how it is applied.

Fittings, Mechanical

Using the water pressure of an air compressor Hydraulic aggregate, mechanical energy is turned into fluid pressure. Hydraulic pumps work by producing a vacuum at the injector intake and forcing liquid from a reservoir into an intake line and then to the compressor. Mechanical stress drives the liquid into the hydraulic fluid by sending it to the pump output.

A hydraulic motor, which is a mechanical actuator, converts hydraulic pressure and flow into torque (or a twisting force) and ultimately rotation. Hydraulic motors can be combined with master cylinder and hydraulic pumps to form a hydraulic driving system. Hydraulic gearboxes may be created when hydraulic motors are combined with hydraulic pumps. While some hydraulic motors run on water, the overwhelming bulk in today’s corporate operations, including the ones in yours, are driven by hydraulic fluid.

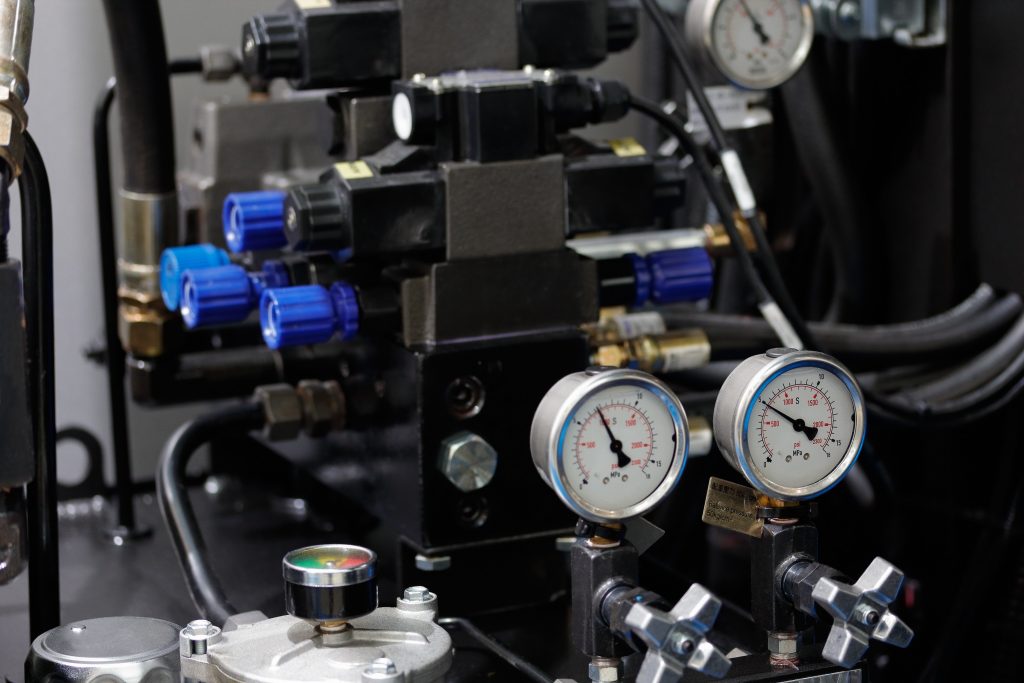

As a result Hydraulic aggregate, hydraulic energy, like other energy sources, must be regulated by utilising an adequate power separating mechanism that prohibits a physical burst of energy. To alleviate pressure, certain systems need the discharge of stored hydraulic energy. Additionally, persons performing emergency shutdown must confirm the release of stored hydraulic power generation (typically evidenced by 0 pressure on gauges) before operating on equipment.

The field of hydraulics is intriguing, and this technology has a rich history. until the present day, hydraulic technology has seen some incredible advances. Since the mediaeval era, water has been utilised to power technology all throughout the world. Regardless of wether you work in an industry that relies on hydraulic pumps or you’re simply fascinated by all things technology and science, starting to learn about the multiple elements of hydraulic equipment is a challenging and difficult process Hydraulic aggregate, and hydraulic power packages are a main focus of many mechanical devices. Hydraulic-powered equipment are utilised in a variety of sectors and may be found in a variety of forms and sizes. While certain devices demand the kind of power that only these independent power packs can deliver, others rely on a built-in power source. They also have a slew of other perks that might help a variety of enterprises.